|

| May 03, 2016 | Volume 12 Issue 17 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

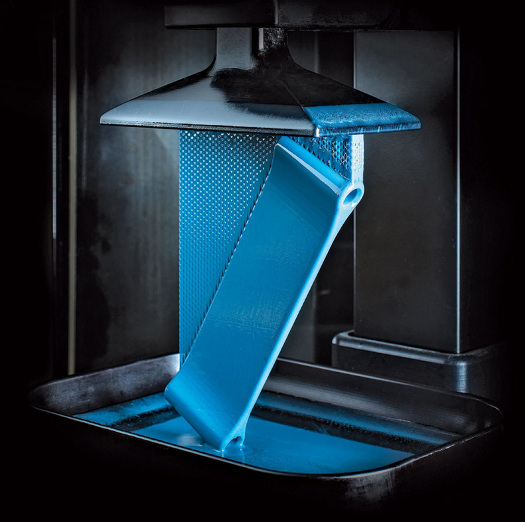

'Terminator' 3D printer now available to the masses

Inspired in part by a scene in Terminator 2 (really!), the new Continuous Liquid Interface Production (CLIP) 3D-printing technology from a company called Carbon3D harnesses light and oxygen to grow objects from a pool of resin instead of printing them layer by layer -- and now you can have it in your shop or office.

It's called the MI additive manufacturing machine, and it really does have the potential to bring some serious usable magic to certain prototyping and low-volume manufacturing efforts.

While traditional approaches to additive manufacturing make tradeoffs between surface finish and mechanical properties, the M1 produces high-resolution parts (for both functional prototyping and production-quality parts) with engineering-grade mechanical properties and surface finish.

Over the last year, Carbon has been working with select early customers in industries as varied as automotive, aerospace, medical, and athletic apparel to test the CLIP technology and machines. Customers including Ford, Johnson & Johnson, BMW, and others have already tested parts in high-stress production applications, such as automobile engines and interiors.

The M1 is being used to shorten product development cycles, address new lightweight, high-strength geometries, and produce customized medical devices. (See Designfax article on Ford using CLIP 3D-printing here.)

VIDEO: Since December 2014, Ford has been working with Redwood City-based Carbon3D, which developed Continuous Liquid Interface Production technology (CLIP), a 3D-printing technology that grows parts from UV curable resins at speeds as much as 25 to 100 times faster than conventional 3D-printing processes. The resulting parts boast mechanical properties that are applicable for a range of needs for Ford vehicles, including high-quality automotive-grade parts.

Carbon3D's MI machine.

The machine features a slick, hands-free foot-activated door. The build envelope is 144 mm (W) x 81 mm (D) x 330 mm (H).

Materials

As part of the M1 product unveil, Carbon is introducing seven proprietary resins, enabling the use of complex chemistries to create parts with a range of mechanical properties. Parts produced using Carbon's breakthrough materials perform similarly to injection-molded alternatives and are suitable for a range of applications.

The new resins include:

- RPU: Carbon offers a family of three Rigid Polyurethanes. RPUs are Carbon's stiffest and most versatile polyurethane-based resin. They perform well under stress, combining strength, stiffness, and toughness. These properties make RPU particularly useful for consumer electronics, automotive, and industrial components where excellent mechanical properties are needed.

- FPU: Flexible Polyurethane is a semi-rigid material with good impact, abrasion, and fatigue resistance. This versatile material was designed for applications that require the toughness to withstand repetitive stresses such as hinging mechanisms and friction fits.

- EPU: Elastomeric Polyurethane is a high-performance polymeric elastomer. It exhibits excellent elastic behavior under cyclic tensile and compressive loads. EPU is useful for demanding applications where high elasticity, impact, and tear resistance are needed, such as cushioning, gaskets, and seals.

- CE: Cyanate Ester-based resin is a high-performance material with heat deflection temperatures up to 219 deg C (426 deg F). Marked by excellent strength, stiffness, and long-term thermal stability, CE is useful for under-the-hood applications, electronics, and industrial components.

- PR: Prototyping Resin prints quickly, has excellent resolution, and performs well enough to withstand moderate functional testing. It is available in six colors: cyan, magenta, yellow, black, white, and gray. These colors can also be mixed to create custom colors.

Connected machine, connected pricing

Hooked up to the internet, the M1 collects over 1 million process control data points per day. This makes it possible for Carbon to provide precise remote diagnostics, assist with print optimization, and improve print quality over time. An internet-connected architecture also ensures that the latest features, performance enhancements, and resins are always available to users, while the browser-based interface enables printer operation inside a network without the hassle of software installs or compatibility problems.

The machine is available via a unique subscription-pricing model. The annual cost includes a hands-on service team. But how much is it, already?

OK, you've waited long enough.

The annual base subscription price is $40,000. There is a three-year minimum term. An extra build platform will cost you $750 a year. Initially, you get one M1 printer, one build platform, on resin sampler pack, and a supply of cleaning and safety items.

Other necessities/options can really add up. An installation and training fee is $10,000. A required accessories pack costs an additional $12,000 (one-time fee) and includes a benchtop engineering resin dispenser, orbital shaker, UV curing flood lamp, and convection oven. The Cyanate Ester Starter Pack is $2,000.

PR resins run $99 (small), RPUs are $199, and CE 220 Amber is $399.

All in all, about $70,000 will get you started and well stocked with resin for beginning year one and your foray into this new type of 3D-printing technology.

Learn more at carbon3d.com

Source: Carbon3D

Published May 2016

Rate this article

View our terms of use and privacy policy